Gibka39 flexible tiles are an eco-friendly, vapor-permeable, and fireproof finishing material with unique properties:

- It is very flexible, so it can be applied to any angle and curved surface (arches, columns, interior and exterior corners, etc.).

- It provides quick and simple installation

- It requires no special tools; it can be cut to size with scissors or a construction knife.

- It is of low weight (about 3 kg/m2), allowing you to reduce the load on the facade as well as the consumption of glue (2-2.5 kg/m2). It also significantly reduces installation time.

- Since flexible clinker tiles are very thin (4 mm), they do not need to be rubbed. It is enough to smooth out the mortar in the joints with a wet brush.

Gibka39 polymer adhesive used with our flexible tiles is a ready-to-use elastic product boasting high adhesive strength. A definite advantage of this product is that it is completely ready to use. It is applied both in interior and exterior works.

Polymer adhesive is used to bond flexible clinker tiles to substrates such as concrete, cement-lime plasters, gypsum plasters, plasterboard, chipboard, OSB, etc.

Color range: 5 adhesive color options: white, light gray, dark gray, beige, black.

Application of the adhesive: The adhesive is available as a ready-to-use thick paste and is applied to the substrate with a 4-mm notched trowel. The joints between the flexible clinker tiles are smoothed with a wet brush.

Consumption of glue per m2 is about 2.3 – 2.5 kg.

The surface of application must be dry, solid, and primed with acrylic primer. The optimum bonding temperature is +10-+20 °C

Gibka39 acrylic primer serves to strengthen the substrate before installation of flexible tiles. It reduces the absorbency of walls and increases their adhesion. The primer can be used under facade tiles on exterior walls or indoors.

Deep-penetrating primer contains tiny particles of acrylic polymers. This allows it to penetrate deeper into the pores of the walls (up to 10 mm). Such a composition does not reduce the vapor permeability of the surface. During curing, the primer forms a crystal lattice with tiny holes, which makes the coating ‘breathe’. This crystal lattice is also what makes the surface perfectly flat.

However, the main task of deep-penetrating priming is to bond fine dust particles and tightly connect the top layers of the base surfaces. This will allow subsequent coatings to adhere tightly to the base coat.

In addition to acrylic dispersions, the primer contains antiseptic. It gives the primer antifungal properties.

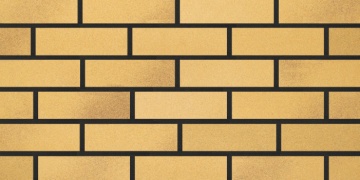

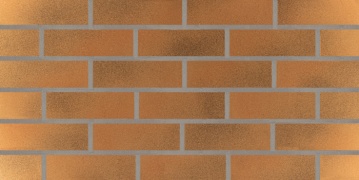

Flexible tiles

Tilsit/White

Art. 1025/1

Flexible tiles

Tilsit/White

Art. 1025/1

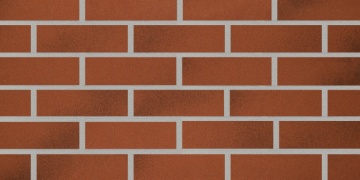

Flexible tiles

Tilsit/Black

Art. 1025/3

Flexible tiles

Tilsit/Black

Art. 1025/3

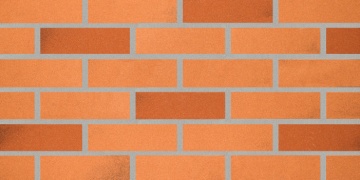

Flexible tiles

Ragnit/Grey

Art. 1020/2

Flexible tiles

Ragnit/Grey

Art. 1020/2

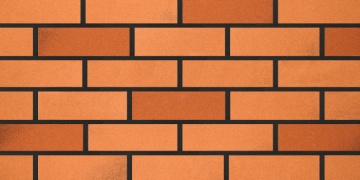

Flexible tiles

Ragnit/Black

Art. 1020/3

Flexible tiles

Ragnit/Black

Art. 1020/3

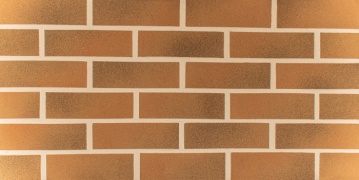

Flexible tiles

Lauke/White

Art. 1019/1

Flexible tiles

Lauke/White

Art. 1019/1

Flexible tiles

Lauken/Grey

Art. 1019/2

Flexible tiles

Lauken/Grey

Art. 1019/2

Flexible tiles

Lauken/Black

Art. 1019/3

Flexible tiles

Lauken/Black

Art. 1019/3

Flexible tiles

Ada/White

Art. 1023/1

Flexible tiles

Ada/White

Art. 1023/1

Flexible tiles

Ada/Grey

Art. 1023/2

Flexible tiles

Ada/Grey

Art. 1023/2

Flexible tiles

Ada/Black

Art. 1023/3

Flexible tiles

Ada/Black

Art. 1023/3

Flexible tiles

Balga/White

Art. 1035/1

Flexible tiles

Balga/White

Art. 1035/1

Flexible tiles

Balga/Grey

Art. 1035/2

Flexible tiles

Balga/Grey

Art. 1035/2

Flexible tiles

Balga/Black

Art. 1035/3

Flexible tiles

Balga/Black

Art. 1035/3

Flexible tiles

Waldau/Grey

Art. 1028/2

Flexible tiles

Waldau/Grey

Art. 1028/2

Flexible tiles

Waldau/Black

Art. 1028/3

Flexible tiles

Waldau/Black

Art. 1028/3

Flexible tiles

Insterburg/White

Art. 1027/1

Flexible tiles

Insterburg/White

Art. 1027/1

Flexible tiles

Schaaken/White

Art. 1029/1

Flexible tiles

Schaaken/White

Art. 1029/1

Flexible tiles

Schaaken/Grey

Art. 1029/2

Flexible tiles

Schaaken/Grey

Art. 1029/2

Flexible tiles

Schaaken/Black

Art. 1029/3

Flexible tiles

Schaaken/Black

Art. 1029/3

Flexible tiles

Louise/White

Art. 1034/1

Flexible tiles

Louise/White

Art. 1034/1

Гибкая плитка

Louise/Grey

Art. 1034/2

Гибкая плитка

Louise/Grey

Art. 1034/2

Flexible tiles

Louise/Black

Art. 1034/3

Flexible tiles

Louise/Black

Art. 1034/3

Flexible tiles

Caymen/Black

Art. 1022/3

Flexible tiles

Caymen/Black

Art. 1022/3

Flexible tiles

Ragnit/White

Art. 1038/1

Flexible tiles

Ragnit/White

Art. 1038/1

Flexible tiles

Ragnit/Grey

Art. 1038/2

Flexible tiles

Ragnit/Grey

Art. 1038/2

Flexible tiles

Ragnit/Black

Art. 1038/3

Flexible tiles

Ragnit/Black

Art. 1038/3

Flexible tiles

Pregel/White

Art. 1017/1

Flexible tiles

Pregel/White

Art. 1017/1

Flexible tiles

Pregel/Grey

Art. 1017/2

Flexible tiles

Pregel/Grey

Art. 1017/2

Flexible tiles

Pregel/Black

Art. 1017/3

Flexible tiles

Pregel/Black

Art. 1017/3

Flexible tiles

Donna/White

Art. 1036/1

Flexible tiles

Donna/White

Art. 1036/1

Flexible tiles

Neuhausen/White

Art. 1033/1

Flexible tiles

Neuhausen/White

Art. 1033/1

Flexible tiles

Neuhausen/Grey

Art. 1033/2

Flexible tiles

Neuhausen/Grey

Art. 1033/2

Flexible tiles

Neuhausen/Black

Art. 1033/3

Flexible tiles

Neuhausen/Black

Art. 1033/3